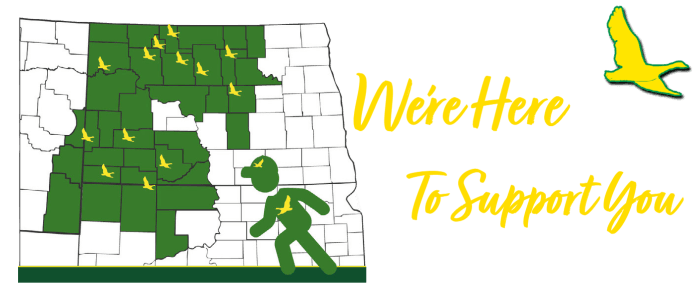

- CALL US

- Kenmare, ND (701) 385-4227

- Minot, ND (701) 852-0767

- Mohall, ND (701) 756-6825

- Stanley, ND (701) 628-2120

- Velva, ND (701) 338-2828

- Rugby, ND (701) 776-5727

- Harvey, ND (701) 324-4631

- Williston, ND (701) 572-6724

- Beach, ND (701) 872-3737

- Bowman, ND (701) 523-3252

- Elgin, ND (701) 584-2681

- Lemmon, SD (605) 374-3373

- Dickinson, ND (701) 225-8123

- Minot, ND (701) 852-4667

- CALL US

- Kenmare, ND (701) 385-4227

- Minot, ND (701) 852-0767

- Mohall, ND (701) 756-6825

- Stanley, ND (701) 628-2120

- Velva, ND (701) 338-2828

- Rugby, ND (701) 776-5727

- Harvey, ND (701) 324-4631

- Williston, ND (701) 572-6724

- Beach, ND (701) 872-3737

- Bowman, ND (701) 523-3252

- Elgin, ND (701) 584-2681

- Lemmon, SD (605) 374-3373

- Dickinson, ND (701) 225-8123

- Minot, ND (701) 852-4667

- International Sales +1 (701) 401-2050

560R MegaWide™ HC² Premium Round Baler

POWER, RELIABILITY & EFFICIENCY YOU NEED WITH PREMIUM PERFORMANCE

CLAIM YOURS TODAY:

2022

560R MegaWide™ HC² Premium Round Baler

Submit your information below and we will reach out to finalize your purchase.

560R MegaWide™ HC² Premium Round Baler Purchase Request - Website Form

Thank you for submitting a request to purchase a 560R MegaWide™ HC² Premium Round Baler from Gooseneck Implement. The sales team is currently working on creating your Purchase Order and will be in touch shortly.

Oops, there was an error sending your message.

Please try again!

MegaWide™ high capacity and cutting (HC²) feeding system

The 0 Series Round Baler family welcomes the first, John Deere, North-American built precutter.

This feed system in front of these machines is the MegaWide HC2. The MegaWide Plus name is known as the industry-leading feed system since its introduction with the 7 Series Balers.

John Deere continues that legacy with the 0 Series. Proven designs of the MegaWide were maintained and improvements were made to key components to gain significant capacity.

-

Cam-Clutch Protection for the Driveline

Learn moreBefore the introduction of the MegaWide HC2 , the cam-clutch protection for the driveline was only available on the 9 Series Premium Balers. It is in the base for the MegaWide HC2 precutter configurations. This driveline pushes the limitations of the baler and the MegaWide HC2 system by offering the best machine protection John Deere can provide.

-

Greasing in One Location

Learn moreAnother feature brought over from the 9 Series Premium Balers and being offered on the 0 Series is the grease banks. All daily greasing can be done from the ground in one central location.

-

Increased Speed & Performance

Learn moreThe roller baffle on the MegaWide HC2 doubled in size from the MegaWide Plus from 10.2-cm (4-in.) to 20.3-cm (8-in.) diameter to allow for increased speeds and performance in larger windrows.

-

Prevent Crop Build-Up on Belts

ButtonAll MegaWide HC2 feed systems will have silage components to limit maintenance and prevent crop build up on belts.

- Driven auger

- Starter roll scraper knife

- Auxiliary take up roller

- For precutter machines only - external belt guides

- External belt guides were designed to dramatically reduce amount of chaff in the gate

- Available through parts - retrofittable through 7 series balers

Primary rotor relationship to knives – front position

Primary rotor from bale chamber

The primary rotor is only available on the MegaWide™ HC² and is located directly behind the MegaWide™ pickups.

This rotor grabs the crop and drags it over the knives to size the crop to a theoretical length size of 2.5 inches.

- For the 4 ft machines, there are 14 slots to receive the knives that are located on the floor of the feed system.

- The 5 ft machines have 20 knives and 20 slots.

Fast-pitch augers on the primary rotor

Industry-exclusive, fast-pitch augers have been placed on the primary rotor to move dry hay and silage past the transition points to avoid plugging.

MegaWide HC2 secondary rotor from bale chamber

The secondary rotor is another component on the feed system that was re-designed from the MegaWide Plus feed system to handle the increased demands of the high-capacity system.

- The secondary rotor in the MegaWide™ HC² is similar in location and design as the MegaWide™ Plus spiral rotor.

- The hex shaft on secondary rotor rotor on the MegaWide™ HC² was increased from 3.2 cm (1.25 in.) from the MegaWide™ Plus to 3.8 cm (1.5 in.)

- The diameter of the tube was increased for additional strength and to prevent silage wrapping

- The number of tines was increased from two to three for additional capacity and flow of crop into the starter roll and chamber.

Drop Floor

Drop Floor

Drop floor – if the baler exceeds capacity and plugs, the MegaWide™ HC² can lower the knife floor from the cab of the tractor to easily feed the plug into the chamber.

- Drop floor is an insurance policy to allow the operator to push the machine knowing that a plug can clear in 30 seconds, not 30 minutes.

- In factory-observed testing with the 2016 test fleet, 99 percent of the plugs were cleared from the cab.

- Floor is self-cleaning – when lowered to feed a plug, it allows chaff that has been built up around the knives to fall through into the windrow.

- This release of crop allows the feed system to stay cleaner

- Allows for easier engagement of the knives and servicing of the knives

- The floor is also responsible for engaging the knives

- Based on lack of success for re-engaging knives in competitive machines, John Deere made sure the MegaWide™ HC2 was built to meet the demands a Deere producer expects.

- Knife-engagement forces on the MegaWide™ HC2 are 10 times that of the New Holland™ Roll-Belt™ 460 CropCutter® Baler. It gives the producer the confidence that if the knives are engaged, they are all up and cutting.

- Once the knives are up, each knife has individual spring protection, limiting bent or broken knives.

- Hit a rock and the knife moves out of the way and automatically re-engages.

Third drive roll

A third drive roll is another feature that will only be offered with the MegaWide HC2 feed system.

- Precutting crop releases additional moisture into the feed system of the baler so the MegaWide™ HC2 feed system added a third drive roll on the number 11 roller to ensure trouble-free bale formation even in the most difficult, high-moisture silage conditions.

- This feature is available only on the MegaWide™ HC2 feed system

-

Clean Crop Retrieval

Learn moreMounted in front of the baler wheels and directly below the bale chamber, the pickup hugs the ground for clean crop retrieval. Hay movement is minimized.

- V-Belt Driven

- Large reel shaft and reel bearing

-

Low-Profile Pickup

Learn moreThe small-diameter, low-profile pickup allows for good ground gauging and clean crop retrieval.

- Handles large, heavy windrows of hay and high-moisture crops

- Feeds hay directly to the forming chamber to reduce crop loss

- Low-profile pickup minimizes hay lift to reduce chaffing and retain hay quality

-

Reduced Hay Loss

Learn moreSide flares prevent hay from blowing off of the pickup ends, which reduces hay loss.

-

Straight-Edged Bales

ButtonThe closely-spaced pickup teeth extend to the baler side sheets to help build straight-edged bales.

-

Contoured Compressor Rods

ButtonStandard on regular pickups, compressor rods are contoured to control hay over the pickup radius for positive feeding. The compressor rack can be adjusted upward or downward to match the volume of material in the windrow and can be easily removed to match crop conditions.

-

Match Field Conditions

ButtonThe adjusting crank positions the pickup to the desired operating height to match crop or field conditions.

automatic electric-tie option

The automatic electric-tie option using BaleTrak™ Pro monitor allows for more productivity. The monitor sounds an alarm for near-full, full, and oversized bales.

Monitor beeps once to notify the operator to even-up the bale prior to reaching the desired size.

Monitor beeps twice when the bale reaches the desired size.

(If the operator continues to feed hay into the baler, the monitor will sound continuously to warn of an oversized bale.

Bale shape bars are not available on the 440E or 450E Round Balers.

The 440E and 450E Round Balers allow for adjustment of twine settings from the cab by using the BaleTrak™ Pro Monitor.

BELT features

Exclusive DiamondTough™ belts with plate-type splices

-

Staggered Belts

Learn moreJohn Deere's 178 mm (7 inch) wide diamond-tread design ensures fast bale starts and grips the bale to prevent slippage and reduce chaffing. The treads are self-cleaning to reduce carryover. The belts are staggered to reduce the loss of fine material and are closely spaced to contain the hay for fast, easy starts.

The belts enclose 91 percent of the bale width to reduce loss of fine material and retain hay quality.

The staggered belt roll design enables any loose hay under or behind the belts to be returned to the pickup and into the baler. This design helps to prevent buildup at the front of the baler, which could cause hay loss and belt or splice damage.

-

DiamondTough™ Triple Weave Belts

Learn moreEvery baler in the 0 Series Family uses DiamondTough™ belts. Belts are constructed using a patented triple-weave process of nylon and polyester materials.

They have the strength to handle heavy shock loads and help maintain consistent belt length.

The DiamondTough™ belts are more puncture and tear resistant than other belts on the market and provide improved belt life and reliability.

-

Plate-Type Splices

Learn moreAll of the 0 Series Balers use the plate-type fasteners.

This closed-loop design uses a plate fastener with pre-assembled rivets that lock the fasteners into the belt, providing a powerful vice-type grip on the belt.

- The plates and rivets are manufactured from high-tensile stainless steel.

- Strong belt splices mean less maintenance and more productivity.

- The loop area is cold forged, making it extremely wear resistant in the coupling area, resulting in a very long cycle life.

- The spring steel pin is notched and locks into the splice connection without having to bend the pin or use external retainers.

UNIFORM BALE DENSITY

Vertical Forming Chambers maintain uniform bale density.

1

Dense Core

As the hay enters the forming chamber from the pickup, belts immediately turn the hay to form a tight, dense core.

2

Compression

Incoming hay then feeds between the bale and the lower gate roll. Hay is tightly compressed into smooth, dense layers as it enters the bale.

3

Reduced Chaffing

Chaffing is greatly reduced to prevent loss and retain hay quality in the bale.

4

Continuous Pressure

The idler arm rises with bale growth, forcing oil from the hydraulic cylinder through a pressure-relief valve to maintain uniform bale density throughout the bale-forming process.

ROUND BALER MODELS

Model transitions for New 0 Series Balers

ROUND BALER MODEL SPECIFICATION

Applicable models for E, M, and R Baler Options

| Previous 9 Series Models | New 0 Series Models | |

|---|---|---|

| 449 | → | 440E |

| 459E | → | 450E |

| 459 | → | 450M |

| 459 Silage Special | → | 450M |

| 469 | → | 460M |

| 469 Silage Special | → | 460M |

| 469 Premium | → | 460R |

| 559 | → | 550M |

| 559 Silage Special | → | 550M |

| 569 | → | 560M |

| 569 Silage Special | → | 560M |

| 569 Premium | → | 560R |

| Baler Option | Applicable Models | |

|---|---|---|

| E (Economy) | Dry hay only | 440E and 450E |

| M (Standard) | Dry Hay, Silage, Pre-Cutter | 450M, 460M, 550M*, and 560M |

| R (Premium) | Dry Hay, Pre-Cutter | 460R and 560R |

KEY SPECS

BALE SPECS

| Belts & Other (Width) | 7 inches | |

| Density Control | Hydraulic | |

| Bale Size Indication | Electronic display on monitor | |

| Number of Bars | Regular Pickup | 4 |

| Number of Teeth | Regular Pickup | 96 |

| MegaWide Plus Pickup | 120 Regular & 8 Mega | |

| High Capacity Pickup | 120 Middle & 8 Mega | |

| Tooth Spacing | Regular Pickup | 2.6 inches |

| Size | Diameter | 32 - 72 inches |

| Width | 62 inches (5 x 6 ft) | |

| Weight | Full-size bale in dry crop | 2,200 lb |

| Max. Allowable for Silage Bale | 2,500 lb |

| Belts & Other (Width) | 8 Belts, 7" Width | |

| Density Control | Hydraulic | |

| Bale Size Indication | Electronic Display on Monitor | |

| Bars | Regular Pickup | 4 |

| Number of Teeth | Regular Pickup | 96 |

| MegaWide Plus Pickup | 120 Regular & 8 Mega Teeth | |

| High Capacity Pickup | 120 Middle & 8 Mega Teeth | |

| Tooth Spacing | Regular Pickup | 6 cm / 2.6 inches |

View additional models available for purchase:

-

560M

Learn More40 Available for Purchase

Vertical forming chamber maintains uniform bale density

Exclusive DiamondTough™ belts with plate-type splices

Automatic electrc-tie option using BaleTrak™ Pro monitor allows for more productivity

Regular pickup offers large feed opening and low-profile, mid-mounted pickup

-

560R

Learn more2 Available for Purchase

Vertical forming chamber maintains uniform bale density

MegaWide™ High Capacity and Cutting (HC²) feeding system

Exclusive DiamondTough™ belts with plate-type splices

Automatic electrc-tie option using BaleTrak™ Pro monitor allows for more productivity

-

560R with Pre-Cutter

Learn more1 Available for Purchase

MegaWide™ High Capacity and Cutting (HC²) feeding system

MegaWide™ Plus pickup with MegaTough™ pickup teeth offers super capacity

Silage configuration

Regular pickup offers large feed opening and low-profile, mid-mounted pickup

All Rights Reserved | Gooseneck Implement