Crop year 2021 has been one for the books. During planting and the growing season, we were always wondering if the crops would germinate, emerge, and be able to complete the crop’s life cycle due to lack of moisture. Currently, the annual cycle of farming is nearly complete. The crops have made it this far and the grain is made. But it is not as simple as just driving the combine over the field to collect the grain that is made. There are multiple pre-harvest decisions that need to be made to maximize grain yield and quality at the time of harvest. The two common pre-harvest operations are swathing and a pre-harvest chemical application.

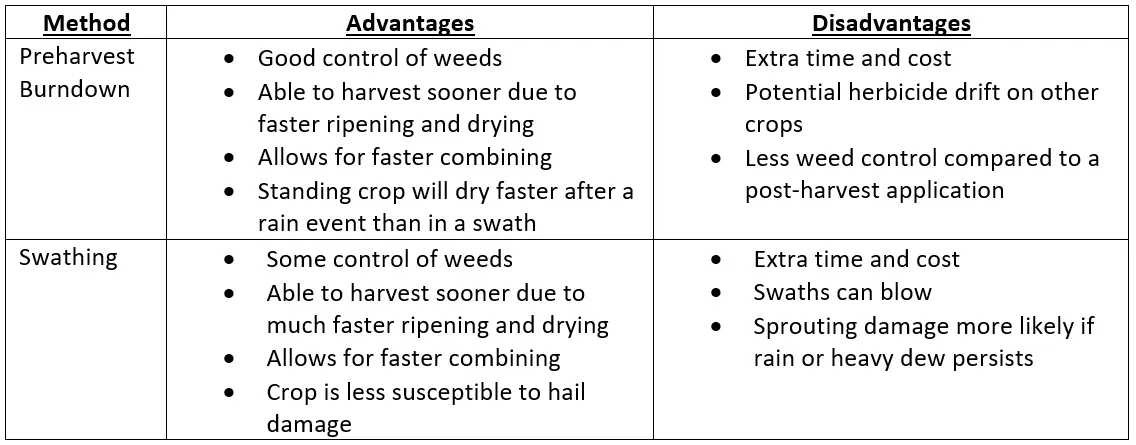

Pre-harvest Burndown

One option to make harvest come sooner and go faster is to use a pre-harvest herbicide application. A pre-harvest application can be done once nearly all the grain is mature. The application will kill weeds and any remaining crop that is still green. Some crops can take a long time to dry down sufficiently enough to be combined and a pre-harvest application speeds up the drying down process and helps the crop go through the combine easier. Pre-harvest applications can be especially important for crops that are susceptible to loss of grain or grain quality, and the longer a ripe crop stays in the field, the more likely is to experience loss of grain or grain quality, usually from wind, rain or hail.

Swathing

Swathing consists of cutting the crop and placing it in rows that become supported above the ground by the remaining plant stubble. The purpose of swathing is similar to that of a pre-harvest burndown. This is an option when crop maturity varies throughout the field, or the environment does not allow the crop to rapidly dry naturally. Swathing can result in crops that dry down faster and more evenly and provides some weed control. The crop is less susceptible to hail damage if put into a swath. However, the grain becomes more susceptible to pre-harvest sprouting in a swath if rain or heavy dew occurs. Swaths can also blow around, especially if the crop is thin. Thin crops also make thin swaths, which can sometimes be difficult for a pickup head to get off the ground.

Swathing

Swathing consists of cutting the crop and placing it in rows that become supported above the ground by the remaining plant stubble. The purpose of swathing is similar to that of a pre-harvest burndown. This is an option when crop maturity varies throughout the field, or the environment does not allow the crop to rapidly dry naturally. Swathing can result in crops that dry down faster and more evenly and provides some weed control. The crop is less susceptible to hail damage if put into a swath. However, the grain becomes more susceptible to pre-harvest sprouting in a swath if rain or heavy dew occurs. Swaths can also blow around, especially if the crop is thin. Thin crops also make thin swaths, which can sometimes be difficult for a pickup head to get off the ground.

Crop-Specific Considerations

Spring Wheat – Growers sometimes apply a pre-harvest application to spring wheat to kill weeds and speed up harvest. However, spring wheat can stay in a field for a week or two after it is mature without too much concern of grain loss or quality, but a few varieties are fairly susceptible to shattering losses, and over time the grain quality will slowly decrease, which will have a minor effect on the grain price.

Durum Wheat – Grain quality is very important with durum. It is typically rain that can reduce durum grain quality, and a loss in quality can happen quickly and often has a significant effect on the grain price. Therefore, growers prefer not to leave a ripe durum field stand for longer than a week or so. They will sometimes use a pre-harvest application on durum, especially if the field is weedy or uneven. Some companies are now paying a premium for durum with low glyphosate residue and durum is most commonly grown in the western edge of North Dakota where August rains are less common, so pre-harvest applications are usually not made in durum.

Barley – Grain quality is extremely important with malting barley. Rain, and even heavy dews can reduce barley from malting quality to feed quality, which is sold for a much lower price. A pre-harvest application is not permitted on malting barley, but growers still want to get this crop harvested soon after maturity. In order to harvest as soon as possible, sometimes malting barley is combined when it is still quite wet and then it is dried in a bin with fans. Grain quality in feed barley is not too critical. Pre-harvest applications are allowed but there is generally no great hurry to get feed barley harvested.

Oats – Oats are commonly swathed and threshed by a combine with a pickup attachment to avoid losses from shattering. Oats should be swathed when the panicle has turned yellow or brown, and the least mature kernels have changed from green to cream. Oats that are left in the field too long can lose quality, and they can shatter. Straight combining oats can be an option but it is important to make sure there are no green hulls at the time of harvest. Green hulls will affect the oat crop from making milling grade. If the oat crop is left in the field too long before cutting, weather may cause stems to break and reduce yield. A pre-harvest burndown can be used, but growers should be cautious about this option when it comes to oats. Not all oat buyers accept oats that had a pre-harvest glyphosate application because they have a strict limit on the amount of glyphosate residue on the seed, which can hinder their salability.

Corn – Corn is a crop that does not get a pre-harvest burndown and is not swathed. Corn can have some yield loss due to weather events, such as hail, but can typically withstand various weather events without loss of grain yield or quality while it is standing in the field. Corn is typically left in the field until the moisture content is favorable to harvest. There are times corn is even harvested the following spring with minimal crop loss.

Flax – Flax can be swathed, sprayed with a pre-harvest chemical, or straight-combined. Flax stems can be very difficult to cut, especially if they are still green, and pre-harvest applications or swathing can make combining easier. If flax is swathed, a swath roller may be necessary to push the swath into the short stubble. Shatter loss and reduced grain quality are usually not common concerns of mature flax.

Lentils – Lentils are rarely swathed but often receive a pre-harvest application. Lentils have limited in-season herbicide options, so fields can be weedy, making a pre-harvest application helpful. Additionally, lentils can exhibit shattering and grain quality losses, so growers want to harvest them shortly after maturity.

Peas – The two major types of field peas in North Dakota are the green and yellow peas. Green peas are typically used for human consumption and have higher quality requirements whereas yellow peas are commonly used for animal feed. For green peas, harvest management is especially important to maintain the high-quality for human consumption or seed. If the crop has quality problems like bleached, split, or cracked seed it will then be bumped to the livestock feed market, which fetches a lower price. Field pea can be swathed but it is rarely done due to increased harvest losses. Typically, a pre-harvest burndown (desiccant) is used in field peas to improve crop drying prior to straight combining.

Soybeans – Swathing is not done in soybeans but a pre-harvest application is sometimes done in weedy areas of a field. It is beneficial to harvest the crop as soon as it is ready to eliminate crop losses, but similar to corn, there have been times when soybean was harvested the following spring with minimal loss of grain or grain quality.

Sunflowers – The two types of sunflowers in North Dakota are confection sunflowers and oil sunflowers. Seed quality is important for confection sunflowers since they are used for human consumption. Oil sunflowers are typically used for oil so quality isn’t as important. Sunflowers are typically harvested at the end of September or October so most years the seed drying process is facilitated by a killing frost. However, a pre-harvest burndown can be applied to sunflowers to help the drying process but the specific hybrid and first frost date can determine if a pre-harvest application is needed. The early season hybrid more than likely won’t see a killing frost, and could therefore dry down slowly, so this is where a desiccant can reduce losses due to inclement weather, lodging, and bird damage. However, a later season hybrid will more than likely start the drying down process due to a killing frost and wouldn’t need a desiccant.

Chickpeas – Instead of ripening like most crops, chickpea will continue growing if there is sufficient moisture. In hilly fields, chickpeas will often be ready to combine in the dry areas but still flowering in the wetter areas. This causes problems if soil moisture is sufficient for growth up to fall frost because there will be green seed in the wetter areas, which causes chickpeas to be downgraded. Because chickpea ripening is often very uneven, in-season herbicide options are very limited, and pod drop and reduced grain quality can occur, chickpeas often receive a pre-harvest herbicide application. This helps control weeds and speeds up dry-down and combining. Growers often have to combine the drier parts of a field and leave the wetter parts to be combined later after they are dry enough. If the wetter parts of a field have small or poor-quality seeds, they should be combined separately, and the grain stored apart from high quality grain.

Dry Beans – Quality is very important in dry beans and there are several ways that growers can ensure quality at harvest. Dry beans should be harvested when still fairly wet to avoid split beans and damaged seed coats, as well as shattering losses. Additionally, rain after ripening can cause seed discoloration, and even green vegetation within the combine during harvesting can stain bean seeds, both of which can reduce quality and the price paid to farmers. Because of this, growers often apply pre-harvest herbicides to ensure that the weeds are killed, and the crop dries evenly and can be cut before some plants get too dry. Growers may sometimes wish to combine only during morning and evening, when humidity is higher and pods are tougher which will reduce shattering losses and damaged beans. Swathing is also an option with dry beans, but this is much less common than pre-harvest applications.

Canola – If canola is being swathed, it’s beneficial to swath at 60% seed color change on the main stem because the branches will have a longer period to fill seed. Swathing may be preferred over straight combining if the crop has uneven stages throughout the field or heavy green weed growth. Canola is a crop that can retain its quality in the swath better than other crops. Swathing also has the potential for reducing shatter losses compared to straight combining. It’s best to stay away from swathing if the crop is thin and short because the windrow will not be held above the ground by the residue and the wind can blow the windrow. There are multiple management decisions to make if the goal is to straight combine canola. Straight combining may be preferred if the crop is short, severely lodged, or the crop has excessive branching. Straight combining has the potential for increased seed size and yield, reduced equipment and labor requirements. The other consideration is if the canola variety has increased shattering tolerance, which is now common and allows for greater flexibility in harvest timing.

Conclusion

There is not a one-answer-fits-all scenario when it comes to pre-harvest decisions. These decisions depend on the grower’s equipment and labor availability, type of crop and variety, current and forecasted weather, grain storage and drying facilities, harvest timing, etc. This is why a crop consultant’s favorite phrase is “It depends.”